- __

EC Prime™

Enhanced conductivity engineered solution that offers the ability to design fracture channel patterns utilizing computational fluid dynamic modelling. Custom engineered treatments for specific reservoir rock properties enhance conductive flow paths with new proprietary ultra lightweight proppant.

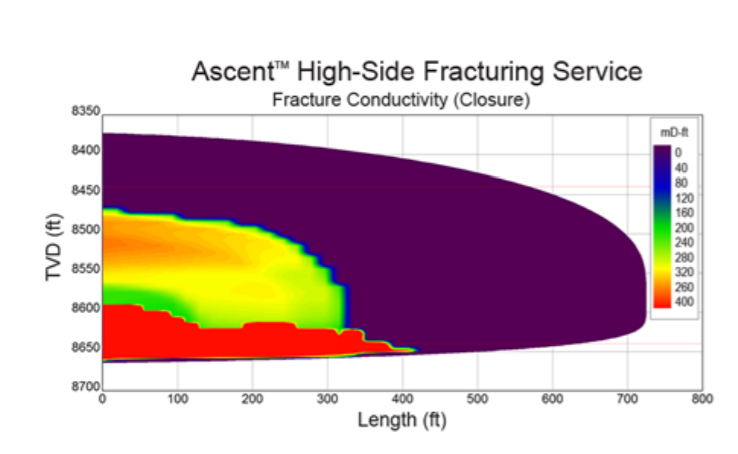

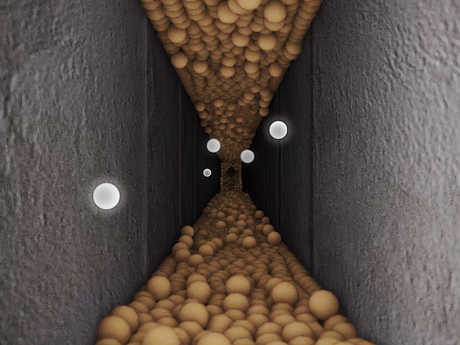

Pillar fracturing has become a common way to try to increase production because, when it works, it can create high-conductivity pathways rather than forcing hydrocarbons to flow through a dense, low-conductivity proppant pack. But the pillars are often too far apart to adequately support the fracture, and can collapse, creating pinch points and blockages that can slow or halt production. Our EC Prime™ enhanced conductivity fracturing service maintains your flowpath over the long term, enabling higher production rates and higher ultimate recovery than conventional pillar fracturing services. By engineering the pillar locations to match the properties of your formation, and by placing a smaller amount of LiteProp™ Prime 108 ultra-lightweight proppant between the pillars, the risk of fracture closure—and of diminished production—is greatly reduced.