- __

- __

TesTrak™

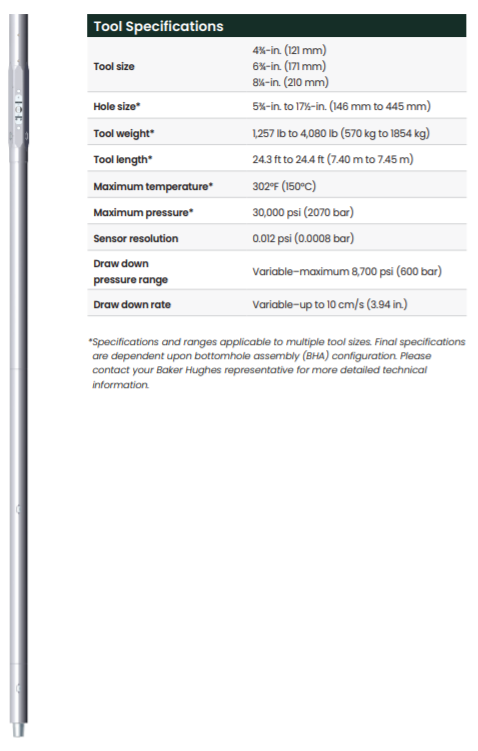

The Baker Hughes TesTrak™ formation-pressure-while-drilling service offers precise,

answers to critical questions on downhole formation pressure and mobility. Gathering

pressure data while drilling allows operators to monitor real-time downhole conditions

while improving rigsite safety, drilling efficiency, and wellbore placement decisions;

besides standard reservoir and petrophysical analysis related to pressure gradients,

fluid contacts, reservoir compartmentalization and others.

Our TesTrak™ LWD formation-pressure testing service offers real-time formation pressure and mobility data. The service delivers critical answers while drilling for improved wellsite safety, enhanced drilling efficiency, increased knowledge of the reservoir, and optimized decision-making. Our TesTrak service improves your operational efficiency and decreases your risk and cost.

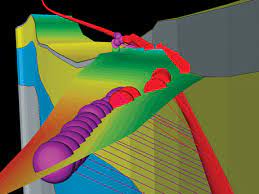

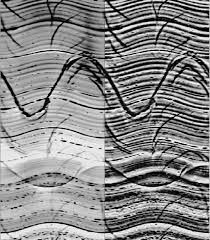

The service’s accurate pressure measurements while drilling can be used to update the geological model in real time. This includes reservoir connectivity, compartmentalization, and the identification of sealing faults to start planning completion and production earlier.

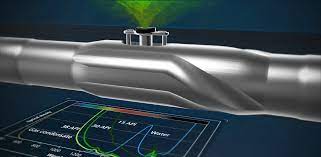

Using the system's high-resolution, transmitted pressure data, you can easily identify reservoir fluids in real time using pressure-gradient analysis. This improves overall operational efficiency compared with the alternative wireline.

With the TesTrak formation pressure tester, you can calibrate models using the near-bit TesTrak device's direct pore pressure measurements. This reduces uncertainty and significantly improves wellsite safety. In addition, real-time pressure management decreases the risk of differential sticking and can optimize penetration, minimizing drilling costs.

Accurate and reliable real-time information leads to better decisions. Using TesTrak data, the reservoir model can be updated to optimize mud programs, casing programs, reduce overall cost, and refine well paths for maximum productivity with increased revenue as a result.