- __

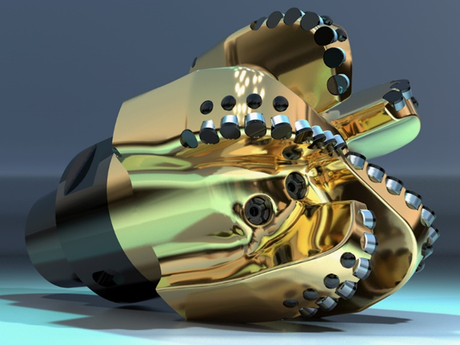

EZReam™ casing and liner reaming shoe

The Baker Hughes EZReam™ casing and liner reaming shoe reduces drilling costs by reaming faster through long, challenging intervals while ensuring casing and liner systems successfully reach total depth on the first attempt. This robust steel-body reaming shoe incorporates a unique design for efficient reaming and faster drillout. It is the industry’s only steel reaming shoe that is drillable with a standard PDC bit. An optimized, tapered profile and heavy-duty cutting structure engage and eliminate obstructions, improving borehole quality and allowing completion equipment to pass through. PDC cutters in the gauge area provide a side-cutting action to aggressively open up tight spots and wipe away low-side cuttings beds. Tungsten carbide elements in the nose and shoulder work to clear ledges and bridges.

Ream out longer intervals in less time and lower risk with the EZReam™ Casing and liner reaming shoe from Baker Hughes. Our heavy-duty casing/liner shoe lets you reach total depth (TD) through the most challenging hole sections, even severely compromised boreholes.

The EZReam technology features a durable tungsten and polycrystalline diamond compact (PDC) cutting structure for faster reaming speeds. The tool’s 360-degree gauge offers added stability to further improve reaming efficiency. The tool is also undersized to promote a smooth transition of the liner through the predrilled hole.

And as the industry’s first steel reaming shoe to offer a secondary bypass port, the EZReam technology lets you continue normal circulation or cementing, even in the event of nozzle plugging.

Once reaming is complete, the tool is drillable with a standard PDC or roller cone, in both onshore and offshore applications.

Some reamer shoes might leave an undrilled portion of the nose downhole, which could damage the next bit or BHA. The EZReam technology’s concave profile drills out from the center to the shoulder, thus eliminating this risk. This patented profile, coupled with unique material properties, enable faster, more reliable drillouts than competitive designs.