- __

- __

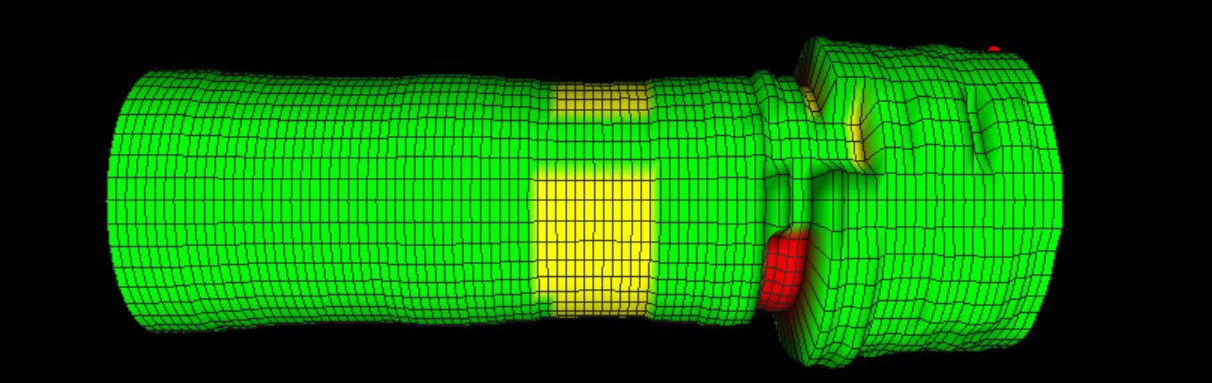

Multifinger Imaging Tool

The Multifinger Imaging Tool (MIT) is available in a range of diameters to suit varying casing and tubing sizes. The tools can be run in combination with other well integrity instruments and Ultrawire™ Production Logging tools. When the MIT tool is run in hole, the fingers are closed to prevent damage. Once at logging depth, a motor is activated from the logging system or by the memory tool and the fingers open. A continuous measurement of the pipe’s surface condition is made as the tool is logged up.

The MIT is available in a range of diameters to suit varying casing and tubing sizes. It is also available in a range of finger configurations from 24 up to 120 individual measurements depending on the required resolution. The fingers increase with the diameter of the tool to maintain maximum surface coverage. The tool can be run in combination with other well integrity instruments and production logging tools. When the MIT tool is run in hole, the fingers are closed to prevent damage. Once at logging depth, a motor is activated to open the fingers and extend them out from the tool body. As the tool is logged up the casing or tubing, the fingers run along the internal wall to provide a continuous measurement of the pipe’s surface condition. The tool includes an inclinometer to indicate the finger positions relative to the high side of the pipe, which allows features to be orientated correctly during data processing.