- __

EZCase™ casing and liner operations bit system

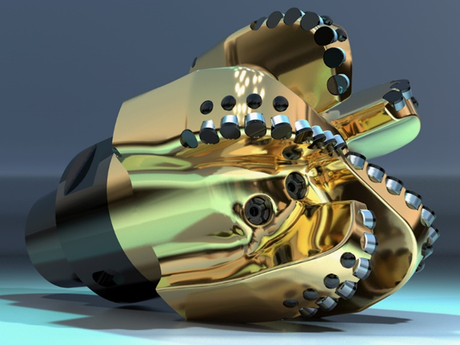

The Baker Hughes EZCaseTM casing bit system enables casing or liner systems to be successfully drilled down to total depth. By combining drilling and casing in one run, the system reduces flat time and provides additional options for problematic wells that cannot be completed through traditional drilling techniques. This nonretrievable casing bit system incorporates numerous exclusive features to enable drilling and reaming over longer intervals, in the most demanding applications, and in a full range of formations. The bit is constructed from a specialized steel alloy with PDC and tungsten carbide cutters brazed directly into a one-piece bit body. The robust crown and cutting structure enables the EZCase casing bit to match the durability, integrity, and rate of penetration (ROP) of standard PDC bits. The bit is welded to a custom steel casing sub to maintain integrity during drilling and drillout operations.

DramaticDramatically reduce your rig time by combining drilling and casing running with the EZCase™ casing bit system from Baker Hughes. Our proven system effectively reams through tight spots and extends your openhole intervals faster—all while decreasing the need for costly remedial work in problematic wells.

The EZCase casing bit system incorporates a steel crown with full polycrystalline diamond compact (PDC) cutting structure, which combines drilling and casing operations in one run. This design not only improves your drilling economics with less nonproductive time (NPT), but it also increases the likelihood of getting your casing or liner to total depth (TD) in unstable formations.

The gauge design’s tapered leading edge minimizes unintentional wellbore sidetracking by reducing reactive torque and sidecutting aggressiveness. And in the event of nozzle plugging, the EZCase casing bit system includes a secondary bypass port option that allows normal circulation or cementing to continue.

After reaching TD, the casing bit system can be efficiently milled out with a roller cone or custom-built PDC drillout bit. Fitting the EZCase casing bit system with our Genesis™ general-purpose PDC bit ensures that additional milling operations are unnecessary.

When drilling through severe loss zones or unstable formations, the EZCase casing bit system helps ensure that you can complete a well that otherwise may have been impossible.ally reduce your rig time by combining drilling and casing running with the EZCase™ casing bit system from Baker Hughes. Our proven system effectively reams through tight spots and extends your openhole intervals faster—all while decreasing the need for costly remedial work in problematic wells.

Reduce costs and flat time

The EZCase casing bit system incorporates a steel crown with full polycrystalline diamond compact (PDC) cutting structure, which combines drilling and casing operations in one run. This design not only improves your drilling economics with less nonproductive time (NPT), but it also increases the likelihood of getting your casing or liner to total depth (TD) in unstable formations.

The gauge design’s tapered leading edge minimizes unintentional wellbore sidetracking by reducing reactive torque and sidecutting aggressiveness. And in the event of nozzle plugging, the EZCase casing bit system includes a secondary bypass port option that allows normal circulation or cementing to continue.

After reaching TD, the casing bit system can be efficiently milled out with a roller cone or custom-built PDC drillout bit. Fitting the EZCase casing bit system with our Genesis™ general-purpose PDC bit ensures that additional milling operations are unnecessary.

When drilling through severe loss zones or unstable formations, the EZCase casing bit system helps ensure that you can complete a well that otherwise may have been impossible